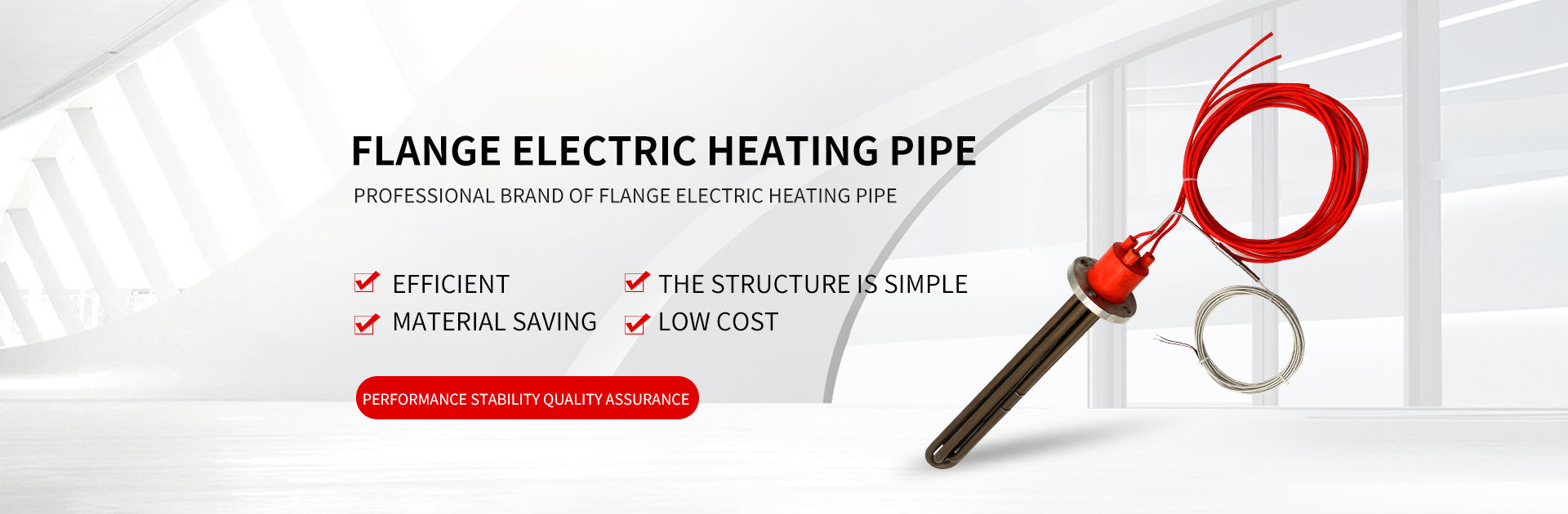

The typical structure of metal tubular electric heating pipe (mass structure) is generally composed of five parts: insulator, sealing material, lead-out rod, filler, electric hot wire, metal casing and terminal.

The spiral electric hot wire and the lead-out rod are located in the center of the metal casing. The manufacturing process is to insert the spiral type electric hot wire into the seamless steel pipe, copper pipe or aluminum pipe. The gap is evenly filled with the insulating and heat conducting medium, such as crystalline magnesia powder (or alumina or clean quartz sand, etc.). Then the pipe diameter is narrowed by the pipe shrinking machine to make the oxide medium dense (density is above 3.3g/cm3), so as to ensure that the electric hot wire is isolated from the air, and the center position does not deviate and touch the pipe wall. That's it. The unit area heat can increase by more than ten times. The service life can also be increased to more than 10 years. Compared with the same heating element with large heat, the tube heating tube can save 5% of the electric material, and the thermal efficiency can reach more than 90%.

Therefore, from the structure of the electric heating tube, metal tubular electric heating tube is widely used, simple structure, reliable performance, long service life sealed electric heating element, can be successfully used in industrial and household appliances, and it is more and more widely used. Hope more users have a clear understanding of the structure and principle of the electric heating tube.

中文(簡體)

中文(簡體)

Scan

Scan